Services

From start to finish our customer support team in Sarasota, FL will follow your order throughout the apparel printing process to ensure that you receive your order correctly and on time. Our highly skilled staff give us the control to make even the most challenging projects easily managed.

We know you have choices when it comes to your purchasing decisions. Let us show you how good our products, pricing and services really are.

Also known as silk screen printing is a method of printing on textile materials using special inks and fine mesh screens stencil.

Also known as silk screen printing is a method of printing on textile materials using special inks and fine mesh screens stencil.

We only use high quality,environmentally friendly, made in USA inks and latest equipment.

Screen printing is consider to be more casual and economic way to decorate textiles. We recommend using this method of printing in order to obtain a high quality product with great durability and affordable price.

Designing the Art

It all starts with the customers idea. That idea is taken to our in house designers who use specialized designing tools to make a computer generated version of that idea. Our designer team incorporates the customer choosen garment and ink colors to create a digital image of the desired product.

Once the design has been completed it is presented to the customer for approval

Art Process

Once the customer approve his design, our designers will process the order. The design will be separated by numbers of colors with a method called color separation. Each color of the design will have its own screen. Before the production, our designer will take the design to the screen department to print each color on a film positive. In cooperation with our production department, they will make an important decision about screen mesh count, ink selection and method of screen printing.

Screen Preparation

Screen printing relies on well constructed screens. Our production team prepares the screens by coating it with photosensitive emulsion. The color separated positive film is attached to the emulsion coated screens and exposed with ultraviolet light. The ultraviolet light burns the design into a mesh to produce stencil. This process is done for each color in the design.

Screen printing relies on well constructed screens. Our production team prepares the screens by coating it with photosensitive emulsion. The color separated positive film is attached to the emulsion coated screens and exposed with ultraviolet light. The ultraviolet light burns the design into a mesh to produce stencil. This process is done for each color in the design.

Screen Printing

Screen Printing

Screen printing is done by transferring the ink through the screen onto the garment. Our production team will load the printing press with screens.

Making a correct color order and choice of ink type is crucial part of the production process. Production team makes sure that your desired design is printed correctly, perfectly placed and aligned to the garment.

Every printed garment will go through a dryer for the ink drying process. Every gament will then go through quality control inspection done by our production manager.

Every printed garment will go through a dryer for the ink drying process. Every gament will then go through quality control inspection done by our production manager.

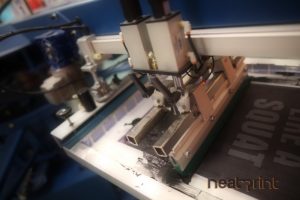

With the Direct To Garment (DTG) you can print on any t-shirt. The quality is just as amazing and is always consistent.

With the Direct To Garment (DTG) you can print on any t-shirt. The quality is just as amazing and is always consistent.

Here are some of the advantages of DTG printing:

- Low Minimum Orders

- No Set-up Fees

- Unlimited Print Colors

- Print on any Color Garment.

- Samples are a Snap

- There is no Heavy Plastic Feel

- Photographs and Complex Images can all be Printed with Unrivaled Clarity and Vividness.

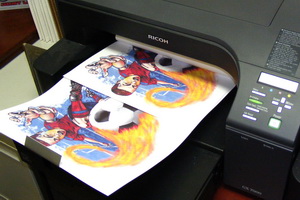

What is Direct to Garment (DTG) Printing?

Direct to Garment printing works similar to your inkjet desktop printer. The unique garment ink is deposited directly onto the shirt, with no burning of screens, setup, or registration involved!

Direct to Garment printing works similar to your inkjet desktop printer. The unique garment ink is deposited directly onto the shirt, with no burning of screens, setup, or registration involved!

In Screen Printing, one screen has to be burned for each color to be printed, this increases the cost for multiple color jobs, and limits the range of colors available. Direct to garment printing allows for unlimited colors to be printed with no added cost.

Since there are no screens and no setup, the minimum required order is very low. You can have five or ten shirts printed, or have ten shirts printed each with a different image. This is especially ideal for family reunions, small businesses, or anything you need personalized.

Modern Approach to Printing

In DTG printing, the ink is applied directly to the shirt, allowing for a flexible feel with no stiffness. This allows the print to be soft and – stretchable. Your image will not crack or peel. For best results, wash your DTG printed shirts inside out in cold water, to keep them looking good for years.

When should I use Direct to Garment Printing?

Direct to Garment printing is perfect for jobs where multiple colors would be too costly, when details, accurate color reproduction is important, if clarity is a strong issue, for small runs, or for personalization.

Direct to Garment printing is perfect for jobs where multiple colors would be too costly, when details, accurate color reproduction is important, if clarity is a strong issue, for small runs, or for personalization.

Screen printing often requires a minimum order because of the time and cost involved to set up a job. Since there are no screens and no setup in Direct to Garment printing, printing one shirt is as easy as printing one hundred.

This is ideal for small companies, printing for resale purposes, or printing samples.

Embroidery is durable, versatile and offers a unique and professional finish.

Embroidery is durable, versatile and offers a unique and professional finish.

When it comes to creating that custom, professional look, nothing does it quite like embroidered apparel and patches.

Our sophisticated commercial embroidery machine can stitch logos and custom designs up to 12 colors on just about any kind of garment including shirts, hats, sweatshirts and iron-on patches.

Embroidery Advantage

It is an ideal alternative to printing especially for uniform and work wear, when garments are intended to be used in an industrial setting or for promotional wear that you want to give a personal touch.

It is an ideal alternative to printing especially for uniform and work wear, when garments are intended to be used in an industrial setting or for promotional wear that you want to give a personal touch.

Embroidery is an excellent way to decorate an item. It always adds that professional look to a garment or other products. There are literally thousands of products that we can embroider. Polo Shirts, Ball Caps, Sweatshirt, Jackets, Beanies Athletic Gear and much, much more.

Quick Service and Re-ordering

The embroidery techniques that we use are quick and clean, thanks to modern digital intervention.

We are now able to ‘digitize’ artwork and designs which means they can be kept on file to be used again and again should extra orders be needed.

Costs and turn-around time

The cost of embroidery, whether for embroidered work wear, corporate clothing, embroidered polo shirts or a custom embroidery project, is subject to the number of stitches in the design; so the denser the design the more expensive it will be.

The cost of embroidery, whether for embroidered work wear, corporate clothing, embroidered polo shirts or a custom embroidery project, is subject to the number of stitches in the design; so the denser the design the more expensive it will be.

It generally costs more than screen printing or digital printing. Typical turn-around time is two weeks.

Transfer printing is great for bold, vibrant, full color designs and single color, individual names and numbers.

Transfer printing is great for bold, vibrant, full color designs and single color, individual names and numbers.

There are a huge array of colors available from fluorescents to metallic print effects and flock velvet effects. This printing technique is used extensively for sportswear and team kits.

Why Transfer Printing?

Unlike DTG printing which can only be used on 100% cotton garments, transfer printing can be used on virtually any fabric including polyester, lycra sports wear, waterproofs and jackets.

Unlike DTG printing which can only be used on 100% cotton garments, transfer printing can be used on virtually any fabric including polyester, lycra sports wear, waterproofs and jackets.

It produces high-quality printing replication and is very fast. It is perfect for next day delivery services.

No setup charges means it’s very reasonably priced!

There are two main types of transfer printing: Vinyl and Paper. Both produce varying results and work with different types of jobs.

Vinyl Transfers

In the Vinyl Transfer process, the design is cut out from a transfer vinyl sheet using a machine, then placed over the garment and heat pressed at a high temperature. This printing technique is limited to 2-3 colors due to the need for perfect vinyl alignment. But it allows us to use special color vinyl and vinyl with special effects for an unique and unmatched visual presentation.

In the Vinyl Transfer process, the design is cut out from a transfer vinyl sheet using a machine, then placed over the garment and heat pressed at a high temperature. This printing technique is limited to 2-3 colors due to the need for perfect vinyl alignment. But it allows us to use special color vinyl and vinyl with special effects for an unique and unmatched visual presentation.

Modern vinyl transfers are tough, durable, bond firmly with the garment and will last a long time if taken care of.

This printing process can be used to print a wide range of garments including t-shirts, sweatshirts, polos, jackets and more.

Paper Transfers

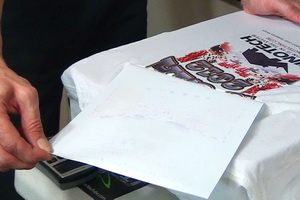

It is the process of printing your designs onto special transfer paper and then applying the transfer paper onto the t-shirt or garment using a commercial heat press. It enables full-color images to be printed very quickly and is a great option for promotional clothing.

It is the process of printing your designs onto special transfer paper and then applying the transfer paper onto the t-shirt or garment using a commercial heat press. It enables full-color images to be printed very quickly and is a great option for promotional clothing.

We can use Transfer Printing when printing onto both light and dark colored T-Shirts and garments.

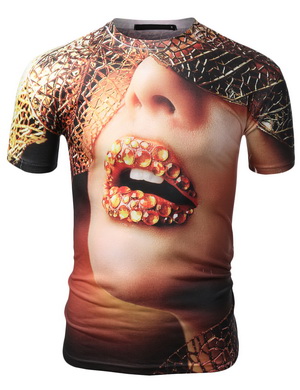

Digital Sublimation Printing is a full color digital print technology that works with polyester substrates and polymer coated substrates. This process is great if you’re looking to print oversized images with multiple colors. Or, if you want to offer something different than traditional screen printing. There is no textured feel to this process.

Sublimation dyes are carried via liquid ink and deposited on a high-release inkjet paper to then be transferred onto the substrates.

Why Sublimation Printing?

The print technology requires a combination of time, temperature and pressure to “transfer” the sublimation dyes into the polyester molecules on the substrate from the high-release inkjet paper.

The print technology requires a combination of time, temperature and pressure to “transfer” the sublimation dyes into the polyester molecules on the substrate from the high-release inkjet paper.

The conventional equipment for transferring a sublimation transfer is a heat press. The result of this process is a virtually permanent full color, high-resolution print that will not crack, fade or peel from the substrate under normal conditions.

Applications

Digital sublimation printing works on white and light colored, polyester or poly coated substrates. Athletic textiles, sports performance apparel, ceramic products and poly coated fiber reinforced plastic are some of the main product categories.

Digital sublimation printing is also used in the creation of trade show displays, snowboards, skis and skateboards. Sublimation can manage high quality photographic art files and vector files as well.

It’s a new trend which has hit the fashion and T-Shirt printing world in recent times.

Which printing method is best for your order?

Screen Printing

Digital Printing

Embroidery

Transfers

Sublimation

Setup Fee Required

Minimum Quantity

50

5

50

5 (vinyl), 25 (paper)

5

Max No. of Colors

up to 8

full color

up to 6

up to 2

full color

Material

cotton, poly blends

cotton only

cotton, poly blends

cotton, poly blends

poly blends only

Special Colors/Effects

Durability

Turn-around time

Cost effective

Product types we can print on

For a full scope of printable products along with all available brands, styles and colors, please visit our online catalog:

Design Service

We turn your ideas into a finished product!

NeatPrint Inc. has a professional design service in Sarasota, FL, to help you turn any idea into a digital design that can be printed using many printing methods we offer. We will lead you step by step through the design process and explain you all the options you have. If it happens that you already have design in a digital format, we can help you with small alterations and adjustments before we prepare it for printing.

Apparel brands we are working with

FAQ

Yes, please refer to the table named “Which printing method is best for your order?” for minimum order quantity.

Yes, depending on the printing method. Please ask our representative. We are flexible with mixing and matching colors and sizes of the garment you’ve ordered for printing. Some limitations apply: if the artwork doesn’t fit small sizes of the garment or you have large sizes in your order as well.

Yes, we can individually polybag each item.

We can use waterbased ink for white & very light garments or discharge ink for darker garments. Please contact us to confirm costs.

Yes, as long as the design remains the same we can change the print color. There will be an additional color change fee.

Generally, items with a wide weave pattern or non-flat surface (i.e. pique polo shirts and fleeces), garments with low cotton content and polyester garments often cause issues.

We can match PANTONE reference numbers when screen printing but we’re not able to match exact colors when DTG printing.

No, we can’t use the same screen’s for printing on the tote bags and t-shirts as the print would be upside down (the opening is on the top of a bag and bottom of a t-shirt)

Yes, our direct-to-garment printer can print onto both white and colored garments. The printer lays down a white layer of ink to provide a base before the colors are printed.

Please note: If your artwork has dark colors and we’re digitally printing onto dark colored garments this may produce a slightly ‘grainy’ effect. You might also see a faint white line around the print – this again is the white base layer. We’ll take a look at your artwork and if necessary will print a sample for you to approve. Direct to Garment Printing is applied manually so allow for some slight variation in exact positional location.

Depending on which customization method we use we need the artwork in one of the following formats:

- Vector Format for screen printing, embroidery or transfer printing:

- Adobe Illustrator, Corel Draw, SVG, EPS or PDF files

- All fonts and strokes should be created to outlines

- High-res PNG files for DTG printing:

- PNG files saved with a transparent background

- Must be saved to at least 150 dpi and at least 100% of intended print size

If you’re not sure or unable to supply any of these artwork files, please just bring whatever you have and we can recommend any changes if necessary.

If you need something designed from scratch, our designers are standing by to help you!

If you need your artwork converting into a print ready format we can help with this.

Just bring the files you have so we can check. Most of the time converting artwork formats is free of charge however If it’s a complex design, there is an artwork charge.

Yes, most of the time, unless a huge order is in the printing process already. For express turnaround orders (3 working days) add 20% to your order total.